Menu

Share this post!

In the realm of plumbing and heating, the evolution of plastic piping materials marks a significant stride in building technology. Gone are the days when metal piping dominated the scene; the introduction of advanced materials like PPR, PEXa, and PE-RT has revolutionized how we think about piping in both residential and commercial constructions.

These materials offer a blend of durability, flexibility, and environmental friendliness, addressing the diverse needs of modern infrastructure. As we delve into the world of plastic piping, it’s crucial to understand the nuances of these materials to appreciate their impact on the industry.

Plastic piping has come a long way from its initial inception, evolving from basic, single-purpose applications to a diverse range of solutions with unique properties and uses. Today’s plastic piping is not just about transporting water; it’s about providing cost-effective, durable, and versatile solutions for a multitude of environments and requirements.

This evolution reflects the industry’s commitment to innovation, sustainability, and meeting the ever-changing needs of both residential and commercial applications.

With these materials available, it’s clear that the modern plumbing and heating industry has a solution for virtually every scenario, each material bringing its unique advantages to the table.

The key benefits of these plastic piping materials are numerous, covering aspects from installation ease to long-term durability. PPR pipes, for instance, are not only lightweight and easy to transport but also offer reduced noise transmission, making them a favorable option in multi-residential buildings. They are also highly resistant to chemical corrosion and scaling, which prolongs their lifespan and maintains water quality.

PEXa pipes excel in areas requiring flexibility, such as in retrofit projects or in areas prone to seismic activity. Their ability to expand and contract without losing integrity makes them a reliable choice in such environments.

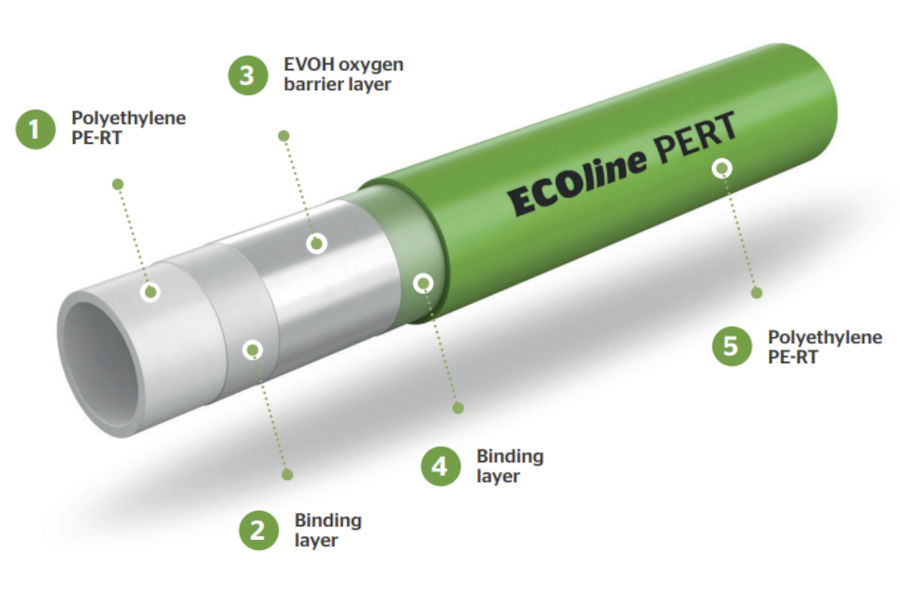

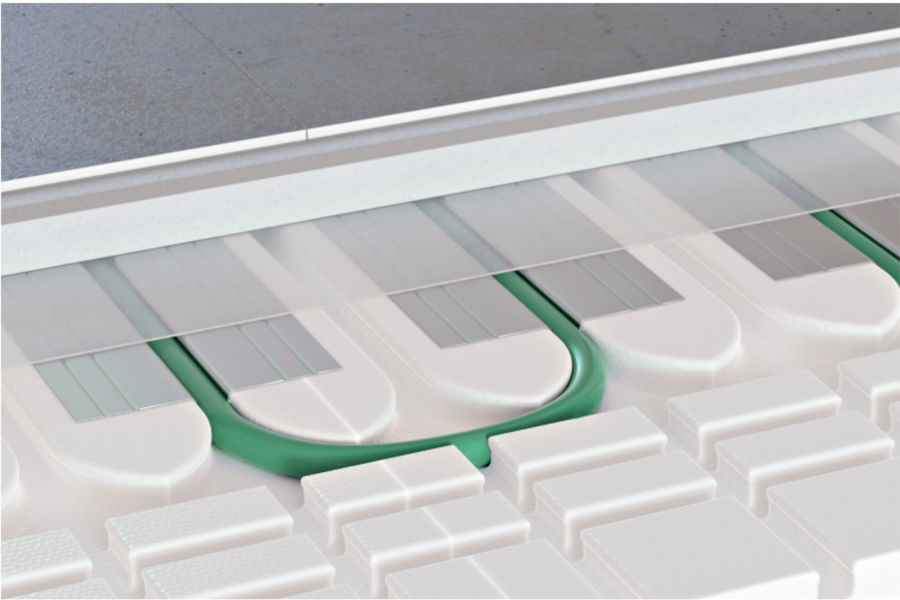

PE-RT pipes bring their unique advantage to the table with their stability at elevated temperatures, making them ideal for hot water systems and underfloor heating applications. Their heat-resistant nature ensures a consistent performance even under fluctuating temperatures.

Here’s a quick rundown of typical applications for these materials:

Selecting the right plastic piping is crucial for the success and longevity of any plumbing or heating project. Factors such as the intended application, temperature requirements, installation environment, and budget play a significant role in this decision.

For instance, in a project requiring high-temperature resistance and durability, PE-RT might be the ideal choice. In contrast, for a system that demands flexibility and ease of installation, especially in retrofitting, PEXa could be more suitable.

Another key consideration is the compatibility of the piping material with the existing system, especially in renovation projects. It’s essential to ensure that the chosen piping can integrate seamlessly with the existing components. Moreover, environmental factors and the need for sustainable, eco-friendly materials should also guide your choice.

Choosing the right plastic piping can be straightforward with our help. Whether it’s for a home, business, or a special project, understanding PPR, PEXa, and PE-RT is important. You might have questions or need advice on what to use for your specific project.

That’s where our team at Nova Supply comes in. We know these products inside out and can give you simple, clear advice. We can help you pick the best piping and answer any questions about installation or the products themselves. If you need help with your piping choices or have any questions, reach out to us. We’re here to help you find what you need without any hassle.

If you need help with your piping choices or have any questions, reach out to us online or by calling our team at 862-846-1360. We’re here to help you find what you need without any hassle.

Ready to discuss your plastic piping and radiant hydronic needs? Reach out to our knowledgeable team today. We're here to provide the expertise and guidance to make your projects a success.