Menu

Share this post!

PPR (Polypropylene Random Copolymer) piping is a versatile and durable solution for various plumbing and piping applications. With its numerous advantages and ease of installation, PPR piping has become increasingly popular in residential, commercial, and industrial settings.

Whether you’re considering PPR or another innovative plastic piping for a new construction project or a plumbing upgrade, understanding the features and benefits can help you make informed decisions and get the best outcome for your piping system project.

PPR piping is a plastic piping system used for conveying fluids in various applications, including plumbing, HVAC, and industrial processes. It is made from polypropylene, a durable, lightweight, and corrosion-resistant thermoplastic.

PPR piping, including pipes, fittings, and valves, is available in different sizes and configurations, so you can use it for a wide range of projects. It is known for its high temperature and pressure resistance and smooth inner surface, reducing friction and preventing scale and deposit buildup.

PPR piping is extensively used in various applications due to its versatile properties and benefits. Some typical applications of PPR piping include:

1. Potable Water Supply: PPR piping is widely used for carrying potable water in residential, commercial, and industrial buildings because it’s non-toxic and non-corrosive.

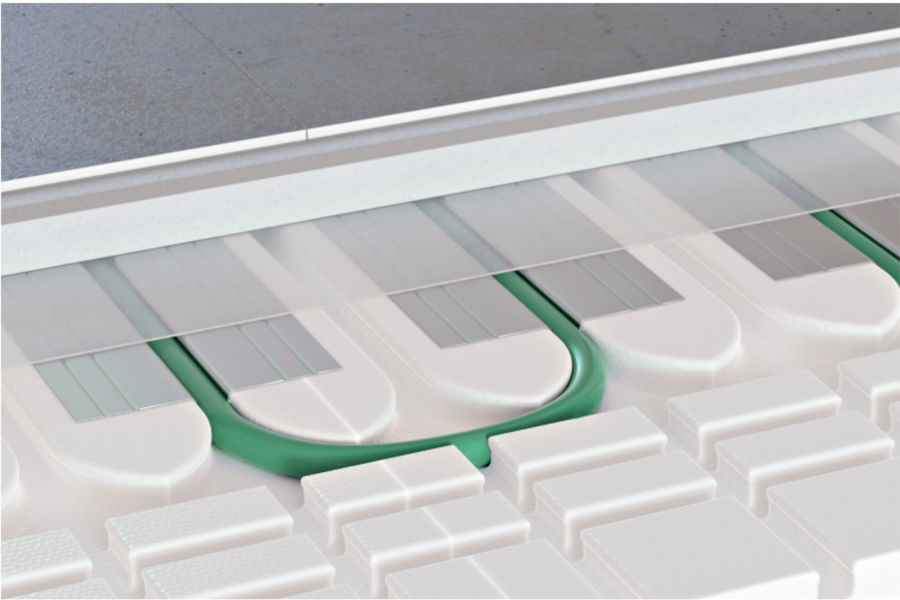

2. Heating Systems: PPR piping is commonly employed in heating systems, including underfloor heating, radiator connections, and hot water distribution.

3. Cooling Systems: PPR piping is also used in cooling systems, such as air conditioning and refrigeration.

4. Chemical Transport: PPR piping is used for transporting various chemicals and fluids in industrial settings, thanks to its resistance to corrosion and chemical degradation.

5. Compressed Air Systems: This piping is suitable for conveying compressed air in pneumatic systems due to its durability and ability to withstand high-pressure environments.

6. Irrigation Systems: PPR is increasingly used in agricultural and landscaping projects for irrigation because of its resistance to UV rays and weathering.

PPR piping offers a versatile and reliable solution for various plumbing and piping requirements, making it a preferred choice for professionals across many industries.

PPR piping has many benefits compared to traditional piping materials. Some of the key advantages of this innovative material include:

Proper installation is crucial for ensuring the optimal performance and longevity of PPR piping systems. So, before you get started with your piping project, consider these essential tips:

1. Plan and Prepare: Before starting the installation process, carefully plan the layout of the piping system, considering factors such as pipe sizing, routing, and access points.

2. Invest in High-Quality Materials: Use high-quality PPR pipes, fittings, and accessories from reputable sources to ensure the reliability and durability of your piping system.

3. Prepare the Pipes and Fittings: Clean the ends of the pipes and fittings thoroughly using a clean, dry cloth or sandpaper to remove any dirt, grease, or debris.

4. Proper Fusion Welding: Use a fusion welding machine to heat the ends of the pipes and fittings evenly until they reach the specified temperature for fusion. Apply the appropriate pressure to join the components securely, ensuring a watertight seal.

5. Allow Sufficient Cooling Time: After fusion welding, allow the welded joints to cool down naturally without applying external force.

6. Pressure Test the System: Once the installation is complete, conduct a pressure test on the piping system to check for leaks or defects.

7. Insulate Exposed Pipes: If the PPR piping is installed in areas prone to temperature fluctuations, such as outdoor environments or unheated spaces, consider insulating the exposed pipes to prevent freezing and condensation.

Choosing the right materials for your project is essential. Nova Supply has a team of experts who can help you select the appropriate products and learn more about their benefits and uses. Whether you want to use PPR piping or other advanced plastic materials like PEXa or PE-RT, we’ll help you get the right tools for the job. Contact Nova Supply today to get started at 862-846-1360 or reach out using our online contact form.

Ready to discuss your plastic piping and radiant hydronic needs? Reach out to our knowledgeable team today. We're here to provide the expertise and guidance to make your projects a success.